In addition to trade wars, lack of water can reduce chip production

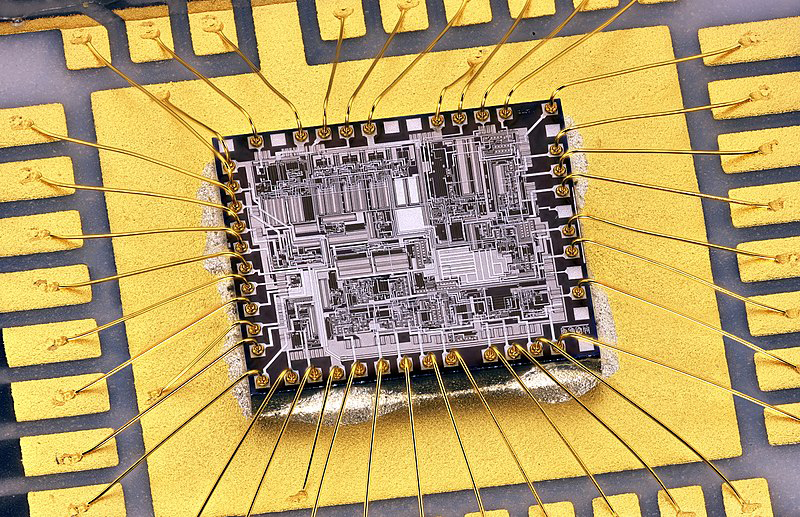

- Semiconductor chips are becoming increasingly impossible and have become geopolitical challenges. They announce a rapid growth in their production in China, the USA and Europe, with the guarantee of extraordinary public funding. But the will of states is not the only thing these industries need: in addition to minerals in limited quantities, water needs are very high and future weather conditions will force important decisions to be taken.

They are present in all electronic devices and the increase in renewable electricity will lead to an increase in their production in such important sectors as energy production, industry, transport and all civil and military devices with screens. Semiconductor chips have become a major geopolitical challenge and Urko Apaolazak begins the cold war of chips: As explained in the report on the technology divide between the US and China, the cold chip war is underway between the US and China. The latest movement of this war has taken place in China, where, following the decision to reduce rare earth exports in July last year, the Chinese Ministry of Commerce announced on 21 December that it will totally paralyse the export of technologies for extraction, treatment and fusion of these minerals. In this context, the word sovereignty in Europe has become fashionable with the meaning of efforts to reduce China’s economic dependence. Unlike the era of globalization, price is now not the only criterion for deciding where to develop production: states want to relocate production of strategic components, although the process is more expensive.

Besides minerals and technique, also water

China and EE.UU. Taiwan’s TSMC company is the world’s leading semiconductor producer. In 2019, it dominated half the world market, with its main business partners being companies from the USA, Japan and the Netherlands. It is particularly advanced in nanometric chips, which produce 90% of them, provided there is enough water for it. TSMC consumed 286 million liters of water per day in 2022. Imagine a 66-meter bucket on a side filled with water every day. These huge quantities are associated with the complex production process: gas extraction, photolithography, strong water, polishing, cleaning and chemical-mechanical polishing of electronic olatas. All these stages require a lot of water, especially polishing and cleaning: throughout the process each chip is washed about a hundred times. In addition, this process uses "ultra clean water" (ultra pure water), and to get a liter of "ultra clean water" you need a liter and a half of running water, increasing the general need for water by 50%.

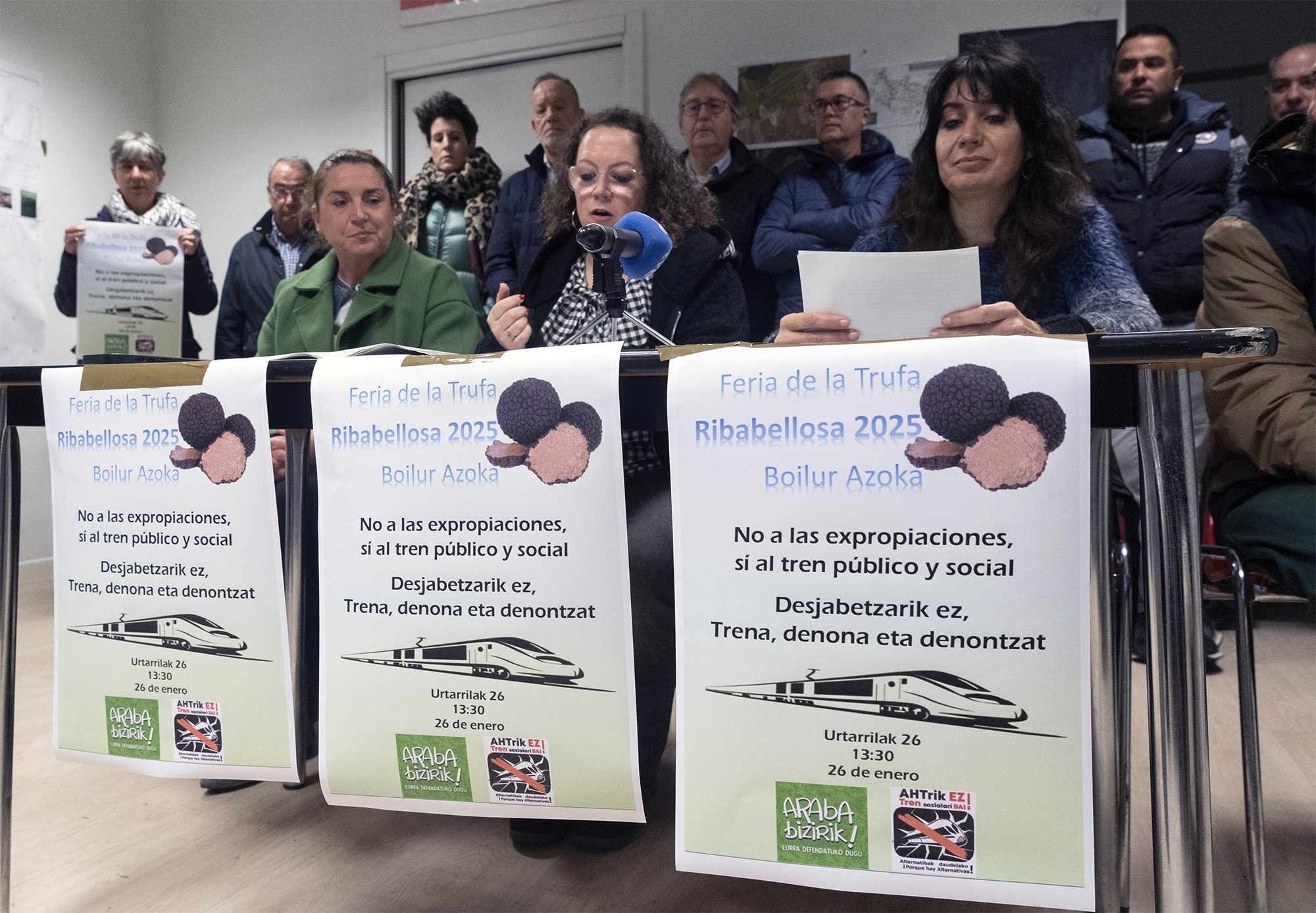

In April 2021, there was no running water in households for two days a week, and 25% of the rice fields ran out of water... to make chip production as difficult as possible.

In 2020, the situation was uncommon in Taiwan: unlike the last 56 years, typhoons did not pass through the island. As a result, in the first months of 2021, the Taiwanese suffered a severe drought, with restrictions on water use. In April 2021, houses lacked running water for two days a week, and 25% of the rice fields ran out of water... to make chip production as difficult as possible. In fact, the government prioritized the semiconductor industry by considering chips to be more important than food and drinking water. Taiwan's importance in this industry became clear. This type of situation will increase in the coming decades, as according to most climate models, in this Pacific region typhoons will be more violent but less frequent.

Different regions, similar problems

Declining production in Taiwan in 2021, as well as geopolitical changes from 2022, mean that more chips are expected to be produced outside Taiwan in the near future. This redistribution of production might suggest that it will avoid the problem of water resources (global supply will not depend on the situation of a single country), but two parameters will make the situation difficult: increased demand for semiconductors, increased variability of water resources and overall decline. In fact, in recent years TSMC and new American companies Intel are planting in Arizona, using water from the Colorado Basin, when they are experiencing historic drought. The water agency of CAP Arizona has clear priorities: drought reduces domestic and industrial use by 3%, compared to 100% water use for crops, i.e. all the growing fields that were irrigated (mainly for vegetable, cotton and maize production) are water free. Intel will also be deployed in the state of Ohio, adding a quarter to the three Columbus city water supply stations by 2028, which will be the world’s largest chip factory. Closer to us, in the city of Crolles, in the area of Grenoble, they intend to double the capacity of the STMicroelectronics factory, with the objective that by 2030 the European Union will increase its productive capacity to 20% of the world’s. In 2021, this factory consumed 11.6 million liters of water a day, which in ten years has increased by 57%. Already in 2020, the Grenoble water supply agency explained that it reached the maximum level of infrastructure use and that this situation entailed risks of supply disruption. In addition, as a Stop Micro farmer said against this expansion, chips are not eaten. If all the glaciers in the Alps are melted, what will the remaining water be used for?

Despite water reuse, water consumption increases

TSMC and Intel are planting new factories in Arizona, using water from the Colorado Basin, while experiencing historic drought

These companies have become aware of the problem of the need for water and are trying to recycle water. Intel announces that it will clearly return more water than it uses by 2030. According to the TSMC, in 2020 86% of the water used by Taiwan was recycled, but, despite being a significant fact, it was not enough to avoid the problems of 2021. In addition, in recent years the recycling rate has decreased slightly, while between 2016 and 2022 water use has increased by 150%. This growing trend is not expected in Taiwan or other countries and may discourage recycling efforts.

If electrification consumption is not reduced, shocks will increase in resource use. There is also a clash between the two meanings of the word sovereignty: competition between states in militarily strategic areas or the ability to guarantee the living conditions of all planets to avoid wars?

Arrantza handi eta industriala defizitarioagoa da sozialki, ekonomikoki eta ekologikoki arrantza txikiaren alboan; arrantza txikiak baino dirulaguntza publiko dezente gehiago jasotzen ditu; eta are, soilik laguntza horiei esker bizirauten du. Horixe erakutsi du Frantziako... [+]

.png)